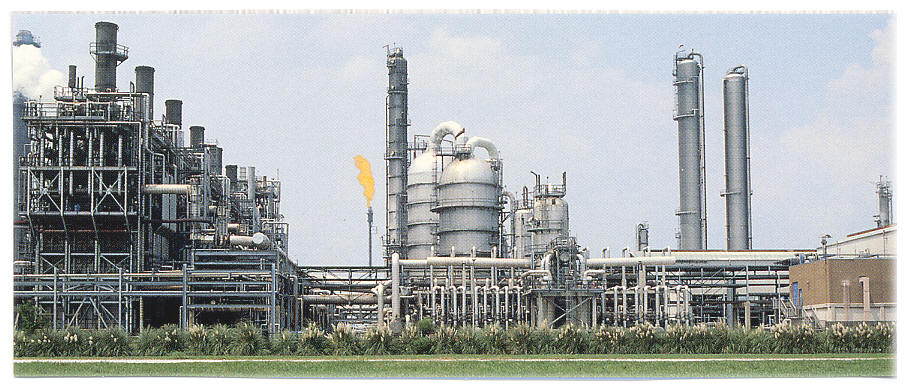

METALLOY

has been a

reliable, quality supplier to the petrochemical and refinery industries for over

50 years. We manufacture high-performance components for the world's largest

chemical engineering firms, existing chemical sites and OEM suppliers.

|

METALLOY has been a reliable, quality supplier to the petrochemical and refinery industries for over 40 years. We manufacture high-performance components for the world's largest chemical engineering firms, existing chemical sites and OEM suppliers. |

INDUSTRY has discovered the benefits of replacing failed or worn process components during shutdowns with components made of advanced alloy metals for higher strength and longer wear. With today's alloys, process systems can operate at a wider range of temperatures, increased production, and higher degree of safety.

METALLOY is an approved supplier of custom manufactured, high strength, high temperature refinery and petrochemical flanges and furnace fittings for many of the world's largest petrochemical engineering firms, contractors, and OEMs. For engineering firms, we routinely provide technical and metallurgical support for longer lasting component life. For cast tube fabricators and contractors, we provide comprehensive, high quality manufacturing capability and flexible production schedules to meet emergency turnaround demands. For OEMs, we provide reliable service and competitive pricing.

Many of our customers are ISO9000 certified. We comply with our customer's quality procedures and recognized societies such as ANSI, ASA, ASME and ASTM. METALLOY is uniquely qualified to handle a full range of sizes and material. If it can be forged and machined, we can do it. We invite customer quality audits throughout the year.

METALLOY maintains all records for materials, production, inspections, testing and shipping. Our record keeping and drawing files assist our customers in bidding and processing their projects. When materials arrive they are checked for conformance to specifications, marked and cataloged. Material test reports are also checked for conformance and filed by heat. No material is accepted into inventory until physical and chemical tests are approved. Drawing dimensions are verified. Quality control starts and ends with quality people, applying quality procedures to quality materials. For over 40 years, our knowledge of the chemical and refinery industries, consistent quality and reliable, responsive service has rewarded us with long-term customer loyalty.